It's still unknown how last week's devastating bridge collapse will affect the world's supply system, despite government workers working to provide a temporary, detour for shipping.

On March 26, a cargo ship that was running out of electricity struck the Francis Scott Key Bridge and caused it to collapse. Six construction workers lost their lives in the collision, which also stopped all shipping into and out of Baltimore.

Authorities now have two laborious chores ahead of them: relocating hundreds of tons of steel and concrete that are clogging Maryland's Patapsco River and rerouting ships that are headed for Baltimore to other ports along the eastern seaboard.

Traffic rerouting is a very difficult task. The river is essential to over fifty different shipping firms and cruise lines, according to The Associated Press. It handled 11.7 million tons of goods last year alone, ranking it as the ninth busiest port for international shipping in the United States.

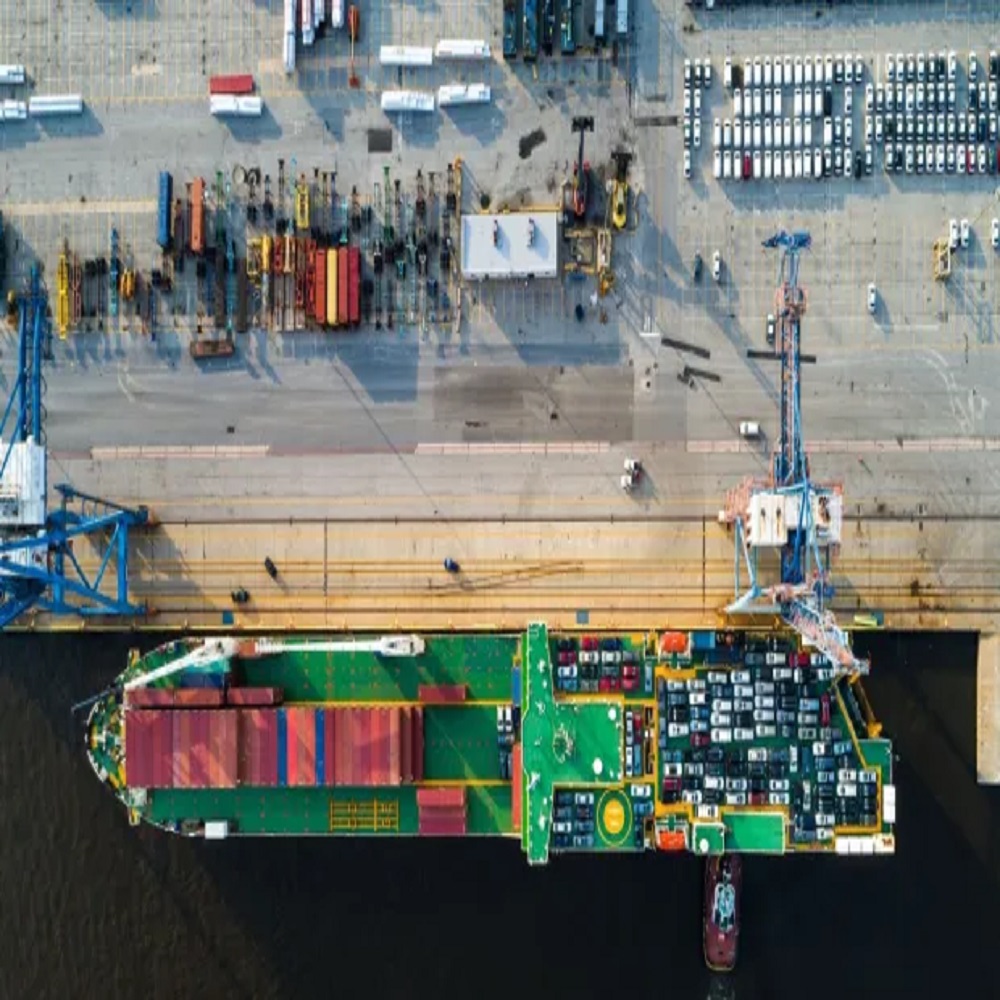

Furthermore, the Port of Baltimore, which “ranks first among the nation’s ports for volume of automobiles and light trucks, roll on/roll off heavy farm and construction machinery, imported sugar, and imported gypsum,” is particularly important to a number of businesses, as PYMNTS reported last week (March 27).

"We are much better equipped to mitigate supply chain disruptions than we were just a few years ago, thanks to increased coordination across the supply chain and new efforts to strengthen both our physical and digital infrastructure," Transportation Secretary Pete Buttigieg assured Americans in a statement two days after the collapse.

Though it would be easy to write Buttigieg's remarks off as election-year optimism, PYMNTS Intelligence data suggests that American companies may currently be in a stronger position than they were even a few years ago to recover from a significant disruption to their supply chains.

PYMNTS Intelligence discovered that businesses had to learn hard lessons from the supply chain interruptions caused by the global pandemic when assembling its research, "Digital Payments: Modernizing Procurement Processes." Many of those businesses improved their supply chain processes as a result.

Based on a survey of 500 CFOs from a wide range of businesses across several industries, the report found that once the pandemic peaked, manufacturers and retailers gave logistics and supply chain enhancements high importance.

In a similar vein, 34 percent of healthcare firms and 40 percent of finance and insurance organizations invested in technology to enhance the supply chain and logistics of their procurement systems.

Enhancing supplier data systems, such as supply chain analytics and real-time inventory information, was another area of attention mentioned by several respondents. Supplier data systems provide businesses with the visibility to expand their supply chains as needed, while also assisting them in better planning and forecasting their inventory demands. This was one important area where supply-chain inefficiencies were visible in the early stages of the epidemic.

According to PYMNTS Intelligence, 39% of manufacturers and 41% of retailers were spending money on updating supplier data and making enhancements to such systems. Comparably, 13% of banking and insurance companies and 12% of healthcare companies were making similar progress.

Along with 22% of banking and insurance firms, 26% of healthcare companies were also investing in better procurement systems and request management and requisition software. In the meantime, to increase inventory visibility, over 36% of manufacturers and retailers were investing in more advanced buy order automation.

Even though catastrophic disasters can have an impact anywhere in the world, they have also driven businesses to make modifications that have improved supply chain and procurement efficiency. Now that another tragedy has occurred that has the potential to disrupt international commerce as well, business owners might find solace in the knowledge that prior lessons may lead to a less catastrophic outcome this time around

Categories

Magazine Editions